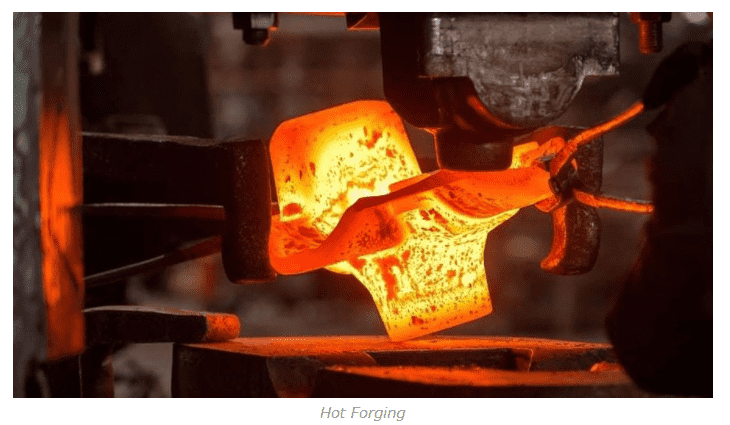

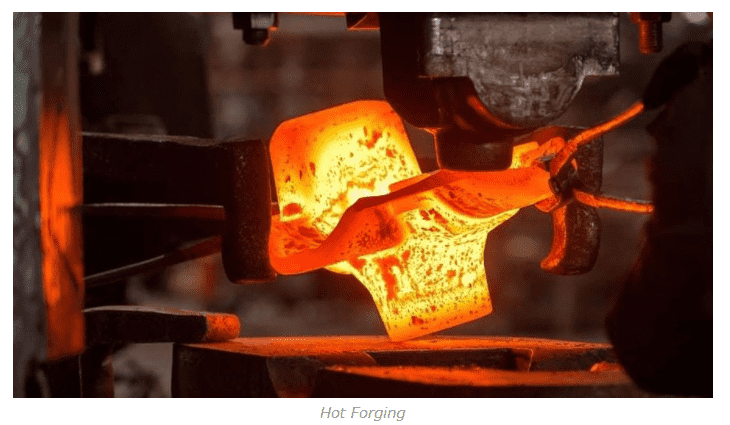

In the hot forging process, the metal is plastically deformed at a specific temperature, and then a predetermined strain rate occurs, allowing the recrystallization process to proceed simultaneously with the deformation, thus avoiding strain hardening. In order to achieve this process, the high temperature of the workpiece (matching the recrystallization temperature of the metal) must be maintained throughout the process. Isothermal forging is also a form of hot forging, in which the die and the material are heated to similar temperatures. Considering the most common cases, isothermal forging is performed on superalloys under vacuum conditions or in a highly restricted atmosphere to limit their passage through the oxidation process.