In the list of importers – 45 countries: Germany, Spain, Italy, Poland,

Portugal, Turkey, South Korea, Japan, etc.

Product Center

aluminium parts

DIMENSIONS: Within 3m, with a maximum of 1.5 tons

casting parts

TECHNOLOGY:Sand Casting/ Precision casting/ Die Casting/ Gravity casting

UNIT WEIGHT:0.1 kg – 50 kg (approx.)

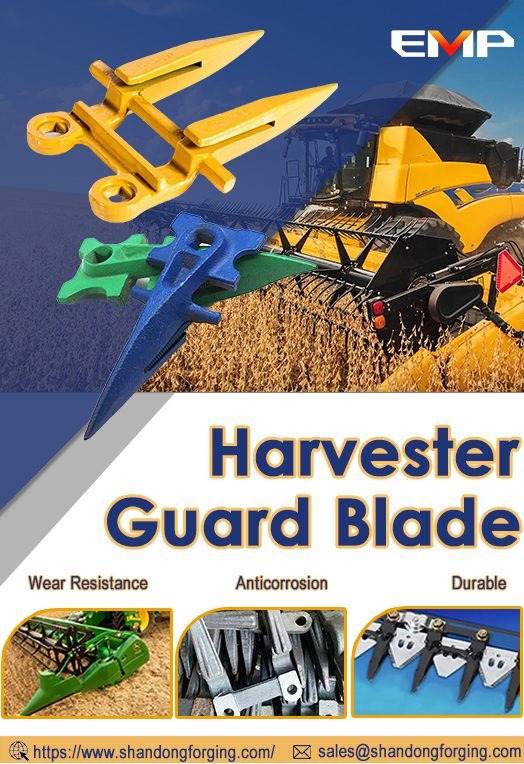

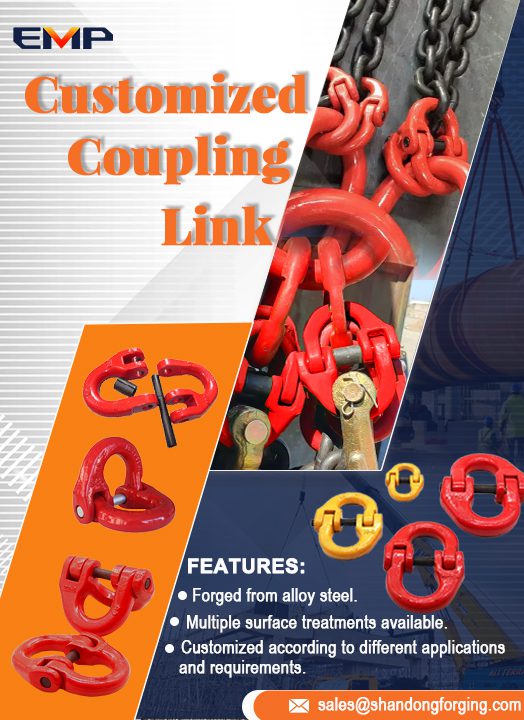

forging parts

DIMENSIONS:1 cm – 300 cm

UNIT WEIGHT:0.1 kg – 20 kg (approx.)

sheet metal parts

EMP is an exporter and manufacturer of CNC parts processing, die-castings, castings and forgings, with over twenty years of experience. We offer non-standard customization and R&D services. All products are produced under strict quality control standards.

About Us

Stop by today; our talented staff will be happy to help you find what you’re searching for!

CEO: Steven Rogers

Core application fields

Construction field

EMP specializes in supplying high-strength, corrosion-resistant architectural metal parts suitable for various construction projects such as steel structures, curtain walls, and piping systems.

energy field

EMP specializes in supplying high-reliability, long-life core components for energy equipment, covering both traditional power and new energy fields.

automotive field

EMP specializes in supplying high-precision, high-performance automotive parts for passenger cars, commercial vehicles and new energy vehicles.

construction machinery field

EMP specializes in supplying high-strength, wear-resistant core components for construction machinery, suitable for heavy equipment such as excavators, loaders, cranes, etc.

marine field

EMP specializes in supplying highly corrosion-resistant and highly reliable ship-specific parts to meet the stringent requirements of ocean-going and inland vessels.

mining field

EMP specializes in supplying highly wear-resistant and impact-resistant mining equipment parts, suitable for harsh working conditions such as crushing, drilling, and transportation.

Free Catalog Download

You can download our brochure to learn more about our products. For any inquiries, feel free to contact us at sales@shandongforging.com.

Free Catalog Download

You can download our brochure to learn more about our products. For any inquiries, feel free to contact us at sales@shandongforging.com.

Add Your Heading Text Here

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Playlist

Add Your Heading Text Here Add Your Heading Text Here Add Your Heading Text Here Add Your Heading Text Here Add Your Heading Text Here Add Your Heading Text Here

We’ll be with you, together bring your project from ideas to market.

You May Have A Question On

Below Problem

The CNC processing equipment of EMP can achieve high-precision processing of ±0.01mm. The surface treatment supports anodizing, hot-dip galvanizing, elector-galvanizing, powder coating and other processes, meeting the wear resistance and corrosion resistance requirements of different industries.

Yes, we have our own R&D team and designers, providing a one-stop service from drawing design to mold development to mass production.

Yes, we have been providing services to OEM parts suppliers in various fields in Europe, America, the Middle East, Asia and other regions for a long time.

We have a full-system laboratory certified by CNAS and a professional after-sales service team, and have established a complete quality control system, which can comprehensively guarantee the quality of components.

We hold certifications such as ISO9001, ISO14001, ISO45001, and SGS, which can ensure that our products meet the requirements of international quality standards.